Research Topics and Interests

The research topics in DM2L are interdisciplinary by nature, spanning over structural dynamics, fluid mechanics, finite element analysis, solid mechanics, and structural reliability. Our long-term goal is to develop effective methodologies for life-cycle performance design, diagnosis, and rehabilitation of civil infrastructure and systems, which integrate extreme event and load modeling, risk and reliability analysis, life-cycle performance design, progressive damage inspection, monitoring, modeling and rehabilitation to develop resilient and sustainable communities.

Our research interests include:

- Damage Modeling: coupled structural dynamics (bridges, buildings, power infrastructure, offshore structures); interactions of fluid (wind, flood, wave, surge, etc.) and structures; corrosion and fatigue due to the impacts from natural and built environment.

- Damage Mechanics: Finite Element Modeling; multi-scale modeling; macro-scale, meso-scale and micro-scale modeling for fatigue and fracture; Computational mechanics.

- Disaster Mitigations: natural hazard modeling and analysis (hurricanes, storm surge, flooding, wind, etc.); fragility and vulnerability assessment; heterogeneous data integration and fusion; system network and optimization.

- Risk Analysis and Reliability Engineering: structural reliability; uncertainty quantification; life-cycle cost analysis; Optimization for decision making; risk assessment.

- Renewable Energy: wind energy, wave energy, vibration based energy harvesting and devices

Current Research Directions

1) Engineering Civil Infrastructures under Multi Natural Hazards Damage modeling of complex structural system

2) Community Resilience Resilience and sustainability of coastal communities

3) Damage Modeling and Resilience Assessment of Power Infrastructure

4) Fatigue Damage Modeling of Structures and Materials

5) Coastal hazards and lifeline infrastructure system

6) Dependency and inter-dependency of connected and interconnected infrastructures and systems

Research Facilities

1) Mechanical testing facilities: Complete facilities for strength, stiffness, tensile creep, cyclic fatigue, and impact testing, as well as for failure analysis are available through IMS center at University of Connecticut. These facilities provide for testing under different loading conditions, temperatures, and environments. Major equipment items can be found here: Institute of Material Science (IMS)

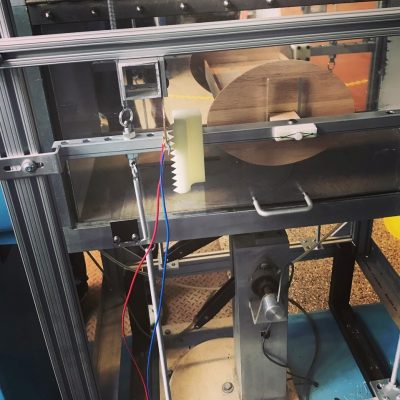

2) Hydraulics laboratory: The Hydraulics Laboratory is located in room 114 of the F.L. Castleman building. The lab facilities are complete with a 4.5 m long hydraulics flume used in conjunction with a 12,000 gallon water storage tank, flow weir, Venturi apparatus, and an acoustic Doppler velocity sensor (ADV) and a rotometer. The hydraulics flume may be used for stream channel flow or engineered channels studies, as well as investigating flow through a simulated piping network.

3) Structural Laboratory: The structures lab is located in room 115 of the F. L. Castleman building. The structures lab is a high bay laboratory equipped with a in-house crane and strong floor, located in room 115 of the F. L Castleman building. The structures lab houses a variety of testing equipment including large-scale SATEC loading machines, MTS actuator for static loading tests, Split Hopkiinson Pressure Bar, Shore-western’s shake table and actuators for hybrid simulation and vibration tests. Also various lab-scale experimental test-beds are developed including steel girder bridge, Pratt truss bridge, two traffic poles, and traffic signal regulator and etc, for validation of basic and advanced theory and technology.

4) Wind Engineering and Energy Laboratory: Wind tunnel, DAQ, Piezo Patch.

Research Sponsors

Support from the following agencies or companies is greatly appreciated.

![]()

![]()