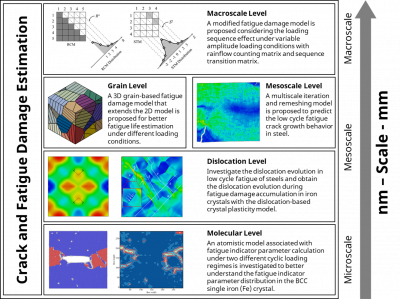

The main goal is to develop a general framework to establish crack and fatigue damage estimation of structural and materials for civil infrastructures at the length scale from microscale, mesoscale, to macroscale subjected to different environmental loading conditions. For this purpose, several research studies have been carried out to help understanding the fatigue behavior of metallic microstructure in different scenarios:

- Zhu, D., Zhang, W. and Ding, Z., 2022. A modified fatigue damage model considering loading sequence effect. International Journal of Damage Mechanics, p.10567895221088029. https://doi.org/10.1177%2F10567895221088029

- Zhu, D., Zhang, W. and Ding, Z., 2022. Preliminary Experimental Investigation of Loading Sequence Effects on Low-Cycle Bending Fatigue. Journal of Aerospace Engineering, 35(2), p.04021125. https://doi.org/10.1061/(ASCE)AS.1943-5525.0001380

- Zhu, D., Zhang, W. and Ding, Z., 2022. Dislocation Density Evolution in Low-Cycle Fatigue of Steels Using Dislocation-Based Crystal Plasticity. Journal of Engineering Mechanics, 148(2), p.04021149. https://doi.org/10.1061/(ASCE)EM.1943-7889.0002063

- Zhu, D., Zhang, W. and Ding, Z., 2020. Atomistic simulation of short crack growth in correlation with fatigue indicator parameter. Journal of Aerospace Engineering, 33(5), p.04020063. https://doi.org/10.1061/(ASCE)AS.1943-5525.0001184.

- Zhu, D., Zhang, W., Yuan, H. and Huang, X., 2020. 3D Grain-Based Mesoscale Modeling of Short Fatigue Crack Growth for Bridge Weldments Considering Crack-Front Evolution. Journal of Engineering Mechanics, 146(2), p.04019133. https://ascelibrary.org/doi/abs/10.1061/%28ASCE%29EM.1943-7889.0001720

- Yuan, H., Zhang, W., Castelluccio, G.M., Kim, J. and Liu, Y., 2018. Microstructure-sensitive estimation of small fatigue crack growth in bridge steel welds. International Journal of Fatigue, 112, pp.183-197. https://doi.org/10.1016/j.ijfatigue.2018.03.015

- Yuan, H., Zhang, W., Kim, J. and Liu, Y., 2017. A nonlinear grain-based fatigue damage model for civil infrastructure under variable amplitude loads. International Journal of Fatigue, 104, pp.389-396. https://doi.org/10.1016/j.ijfatigue.2017.07.026

For microscale level damage estimation, problems related to crack behaviors and damage accumulation of the atomistic model under constant and variable amplitude loadings, as well as (Fatigue indicator parameter) FIP calculation, need to be addressed in the study. The relation between FIP and crack propagation during the crack growth process should be investigated to have a better estimation for the parameters used in mesoscale crack propagation assessment.

For mesoscale level damage estimation, problems related to dislocation evolution in low cycle fatigue of steels also need to be addressed in the framework. The implementation of the grain-based fatigue estimation model, as well as the multiscale iteration and remeshing method on fatigue damage predictions for steels, should be discussed.

After discussing the microscale and mesoscale, the macroscale level damage estimation should be studied to address the loading sequence effects in detail and methods should be provided to help improve the damage assessments, such as the deterministic method and the probabilistic method. The entire fatigue damage estimation framework is shown in Figure. 1.

Figure 1. Fatigue damage estimation framework from nanoscale to macroscale structures and components under different loading conditions.